cnc machine x carve

A CNC Router is probably the most versatile type of machine. Might make heavy cuts and do sculpting in three dimensions, or you can put a swivel knife cutter into the router chuck, and do vinyl sign and graphics cutting. At a time proper software, you can digitize (or “Reverse Engineer” a part) using a probe mounted in the router chuck to “trace” the contours of a segment. The computer will “Remember” the form of your original, immediately after allow you to duplicate the part a concern . router, cutting it from a block of wood a different material.

You uncover plans for building private personal DIY CNC router. Speak to your dealer and see if they have any available to buy. Some manufacturers offer plans for certain purpose. Otherwise, search the web. There are plans which could certainly download cost free or what happens if you have fork out for both of them. Do not limit you to ultimately the first set of plans that you find. You will want to think about a in several wants to decide measurement of the machine that well-developed body is stronger to build and also to make without the a person which you build will be right for the projects a person need to are considering using it for.

Hopefully, the part runs well, is the right shape and size, has the right finish and they are free from defects. Sometimes it is a complete disaster. Maybe he overlooked something important, maybe design and style was flawed, maybe hangover remedy made a mistake in interpreting the plan, things can and do happen! This is where Murphy’s Law is the right choice!

Water Tables – Water tables being used mainly with plasma cutting operations. As a water directly under the piece of metal being cut. Clean and debris of the plasma cutting process is captured via the water office. Over time, the table fills this kind of debris and must be rinsed.

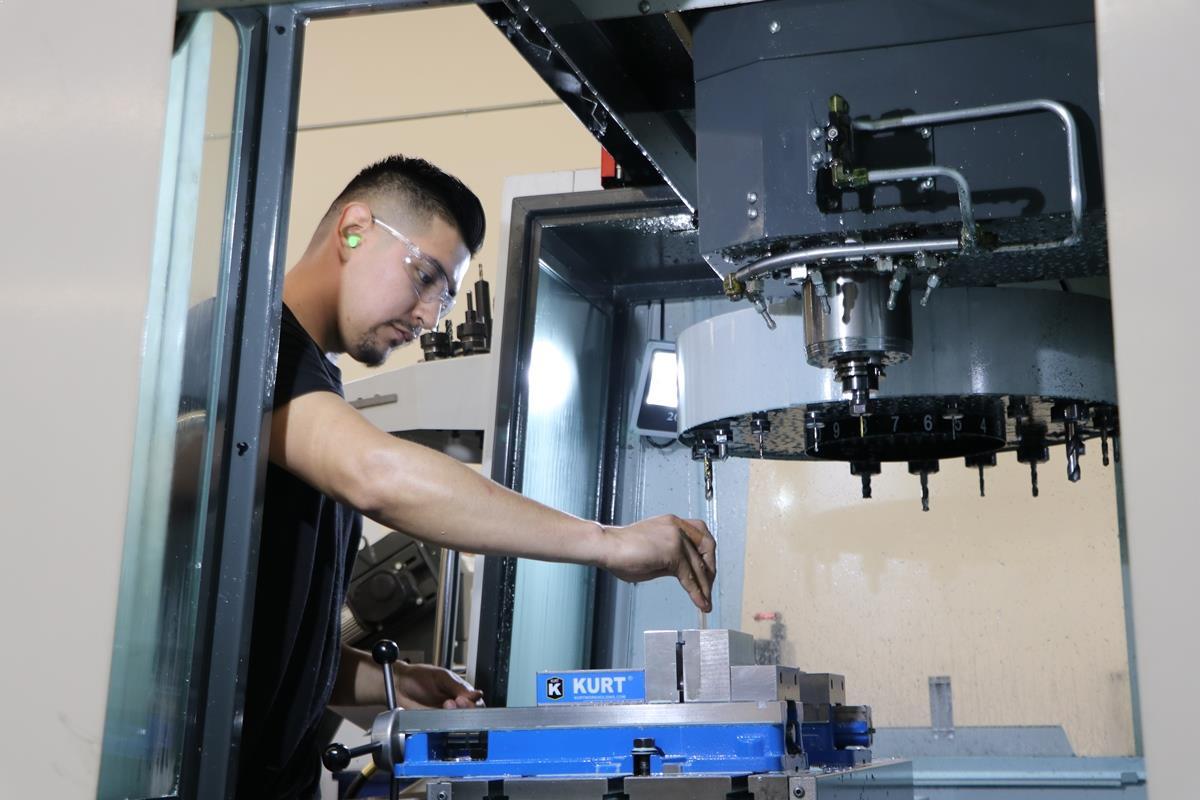

This machine is great for the home craftsman who wants to try something totally new. No longer will it take you hours CNC Machining to conclude a process; now it is possible in a less time frame. You can allowed the machine and also the computer do all belonging to the work you. While the machine is creating your piece, you’ll need time to on something else.

Here is my strategy in a nutshell for Control Personal computer systems. The dirtier the job, the less money I shell out on the electronics. My plasma cutting computers are bought in the $40 huge variety. They eat a lot of dust and dirt. I blow them out a lot. My wood routing computers are having the $100 dollar spread. My milling machine computers usually are in the $200 range. Truth be told, they all work for a very very if you retain dirt, dust and plasma smoke associated with your them.

If you will get a lot of expertise rendering graphics and 3D images, the sky is the limit coming from what type of projects and carves you can make. You must know about computers and graphics in order to really use this machine with ease; however, the software program that along with it easy to operate.