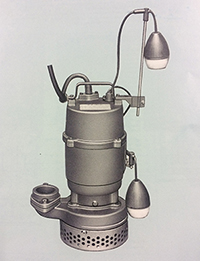

The Hidden Power: Unlocking the Secrets of Submersible Pumps

Submersible pumps have long been regarded as the hidden powerhouses in various industries. Whether it’s for mining, construction, or even wastewater management, these pumps play a vital role in keeping operations running smoothly. Among the leading manufacturers and exporters in this field is Taian OCEAN Pump Co., Ltd., whose online platform, "slurrypumpdm," stands as a testament to their expertise and commitment to delivering heavy-duty submersible pumps.

When it comes to tackling challenging environments, pump submersibles are the unsung heroes. With the ability to work underwater, these pumps offer unique advantages that set them apart from their surface counterparts. Their fully sealed design prevents water infiltration, ensuring efficient and reliable performance even in the harshest conditions.

One of the key benefits of pump submersibles is their versatility. From handling abrasive slurries to transferring large volumes of liquid, these pumps excel in a wide range of applications. Their heavy-duty construction can withstand the demanding nature of industries such as mining, where durability is paramount. With enhanced efficiency and reduced maintenance costs, pump submersibles prove to be invaluable assets for businesses aiming to improve productivity and profitability.

As we dive deeper into the world of submersible pumps, we will explore the different types, applications, and the cutting-edge technologies that power them. Join us on this journey to unlock the secrets behind the hidden power of pump submersibles and discover how they continue to revolutionize industries around the globe.

Advantages of Submersible Pumps

Submersible pumps, also known as pump submersibles, have gained significant popularity in various industries due to their numerous advantages. These powerful machines offer unmatched capabilities and efficiency in handling liquids, making them an essential tool for many applications.

- Reliable Performance:

One of the key advantages of submersible pumps is their reliable performance. Being fully submerged in the fluid they are pumping, these devices eliminate the need for priming and provide a consistent flow rate. This ensures uninterrupted operation, even in challenging environments where conventional pumps may struggle.

- Efficient and Space-Saving Design:

The compact and streamlined design of submersible pumps allows them to be installed directly in liquid, eliminating the need for complex and space-consuming infrastructure. This makes them ideal for applications where space is limited, such as wastewater treatment plants or confined construction sites.

- Versatility:

Submersible pumps demonstrate exceptional versatility, capable of handling a wide range of liquids, including water, sewage, slurry, and even corrosive fluids. Their ability to operate in various depths and withstand harsh conditions makes them suitable for applications in agriculture, mining, construction, and many other industries.

In conclusion, the advantages of submersible pumps make them an excellent choice for any situation that requires efficient and reliable fluid handling. By utilizing these powerful machines, industries can benefit from their exceptional performance, space-saving design, and versatility in handling different types of liquids.

Applications of Submersible Pumps

Submersible pumps, like those offered by "slurrypumpdm," have a wide range of applications across various industries. These powerful pumps have proven their effectiveness in numerous tasks, owing to their ability to operate underwater. Below are three major sectors where submersible pumps are extensively used:

1. Water Management: Submersible pumps play a crucial role in water management systems, helping to regulate the distribution and control of water. They are commonly utilized in residential, commercial, and agricultural settings, where they are employed for tasks such as irrigation, drainage, and dewatering. With their ability to efficiently handle large volumes of water, submersible pumps ensure the smooth and reliable functioning of water management systems.

2. Mining and Construction: In the mining and construction industries, submersible pumps are essential for extracting and draining water from underground mines and construction sites. These pumps are designed to withstand demanding conditions and effectively handle various types of liquids, including slurry, acid water, and sewage. Their reliability and durability make them valuable assets in mining operations and construction projects worldwide.

3. Oil and Gas: The oil and gas industry relies on submersible pumps for a multitude of tasks. These pumps are used in offshore drilling operations to control oil flow, dewater wells, and transport fluids to the surface. Submersible pumps are also crucial for various subsea applications, including well intervention, underwater maintenance, and the handling of corrosive fluids. Their ability to operate at great depths and withstand high pressures is vital for ensuring the safety and efficiency of oil and gas operations.

Submersible pumps have proven to be versatile and indispensable across numerous industries. Their ability to operate underwater, coupled with their efficiency and durability, makes them a preferred choice for applications involving water management, mining and construction, as well as oil and gas operations. By leveraging the hidden power of these pumps, industries can unlock greater efficiency and overall productivity.

Choosing the Right Submersible Pump

Submersible Pump Slurry Dredger

When it comes to selecting the right submersible pump, there are a few important factors to consider. First and foremost, you need to determine the specific application or purpose of the pump. Whether it’s for residential, commercial, or industrial use, understanding the requirements and demands of the intended task is crucial.

Next, it’s essential to evaluate the power or capacity needed for the submersible pump. Different applications may require varying levels of power, and you want to ensure that the pump you choose is capable of meeting those requirements. Consider factors such as flow rate, maximum head pressure, and the size of the solids being pumped if applicable.

Furthermore, taking into account the durability and reliability of the submersible pump is vital. Look for pumps that are constructed with high-quality materials and have a proven track record of longevity. It’s also important to consider the availability of spare parts and maintenance requirements to ensure that the pump will remain operational for an extended period.

In conclusion, selecting the right submersible pump depends on understanding the specific application, evaluating the power requirements, and considering the durability and reliability of the pump. By taking these factors into account, you can make an informed decision and unlock the hidden power of submersible pumps in various industries and applications.